Get To Know Acetate Tow:

Acetate tow is a fiber material derived from wood pulp or cotton, turning liquid when mixed with solvents to create fine filaments. These filaments are then bundled into long continuous fibers known as "tow." Lightweight and durable, acetate tow finds use in various industries due to its versatility.

Acetate tow is utilized in a wide range of products. From cigarette filters to lightweight and breathable fabrics in clothing production, it also contributes to items like plastic bags and Saran wrap. The key processes involved include higher heat and boiling to create the material.

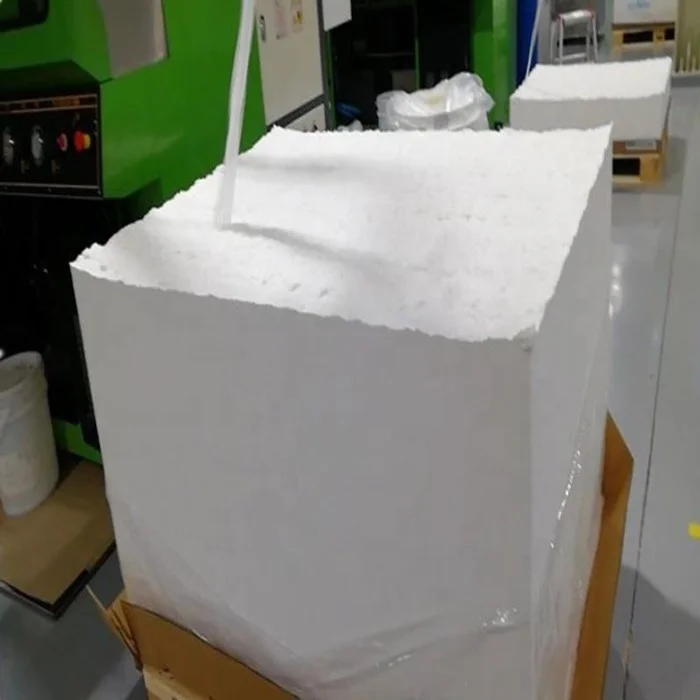

The manufacturing process of acetate tow begins by dispersing wood pulp or cotton through acetic anhydride with sulfuric acid as a catalyst. This mixture undergoes gentle boiling for 12 hours, possibly incorporating white pigmentation, dyes, softeners, or other additives. The resulting liquid is spun into thin fibers, which are then washed, dried, and cut for use in various products.

While acetate tow is a valuable material, its production can harm the environment if not properly managed. Chemicals used in the process can pose risks to wildlife and aquatic life, while the energy-intensive production contributes to greenhouse gas emissions. Efforts to produce acetate tow sustainably involve seeking alternatives, reducing energy consumption, and eliminating harmful byproducts.

Ongoing studies aim to enhance acetate tow's properties such as strength, flexibility, and durability. New designs and patterns are continually developed for fabrics and plastics made from acetate tow, opening up endless possibilities for its applications. Sustainable manufacturing practices and innovative designs ensure that acetate tow remains a relevant and valuable material in the future.

The factory established in acetate tow boasts a large production capacity that includes 500+ sets of machinery and over 300 molds We insist on strict quality control throughout the manufacturing process and ensure that our machines are of the highest quality which meet the strictest standards Every step from CAD-CAM through powder coating and professional assembly is performed with a high degree of precision to guarantee quality and reliability of the products

Fancyco was established in 2004, has established a acetate tow reputation as a leader in the business of printing and packaging products in the past 20 years. As a gold-certified supplier on Alibaba, we marked an important milestone in our commitment towards quality and customer satisfaction.

Fancyco has been able to expand into more than acetate tow countries and areas around the world. In 2015 we positioned ourselves as the No.1 brand for sticker paper and hygiene products in Nigeria and Uganda showing our ability to enter and lead markets by providing high-quality products and exceptional service.

acetate tow has over 25 years expertise in RD and is dedicated to the pursuit of innovation The technology center at Fancyco is supported by an knowledgeable RD team that has an average of more than 15 years of experience We have the ability to develop innovative products and solutions that are able to meet the ever-changing needs of our customers around the world